MIL-DTL-713F

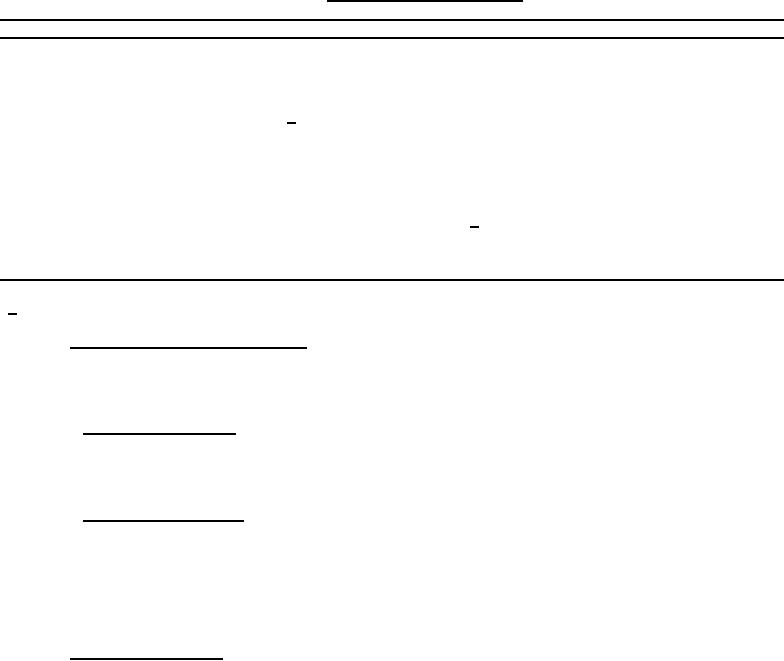

Table III. Visual examination defects.

Examine

Defect

Appearance and

Any cut

workmanship

Chafed or damaged

Finish lumpy or unevenly applied resulting in thin or bare spots, clearly

visible 1/

Type and finish

Not as specified

Color

Not as specified

Cleanness

Overall uncleanness, clearly visible 1/

Identification

Omitted, incorrect, illegible, insecurely attached, or not as specified

1/

At normal inspection distance, approximately 3 feet.

4.2.3

Examination for weight and winding. The sample unit for this examination shall be one tube or spool

of twine. For lots consisting of 500 or fewer units, the sample size (number of sample units) shall be 10. The

inspection level shall be S-3 and the AQL shall be 4.0 percent defective. The lot size shall be the number of tubes

or spools of twine in the inspection lot. Defects shall be as listed in 4.2.3.1 and 4.2.3.2.

4.2.3.1

Examination for weight. A defects with regard to weight shall be considered to exist if the net weight

of a tube or spool is less than the minimum or more than the maximum specified in 3.7. The number of holders

examined shall be utilized in determining the average weight. A lot shall be unacceptable if the average weight is

less than the 1 pound weight specified in 3.7.

4.2.3.2

Examination for winding. Defects with regard to winding shall be considered to exist if any of the

following are determined during inspection.

(a) Improperly or not firmly wound resulting in kinking, knotting, entangling or slippage during

unwinding, or otherwise affecting free unhampered unwinding of twine.

(b) Any length of twine less than 16 yards on a tube or spool.

(c) A total of three or more knots or laid-on ends on a tube or spool.

Testing of the end item. The methods of testing specified in FED-STD-191, wherever applicable and

4.2.4

as listed in table V shall be followed. When the data in the "number of determinations" and "Results reported as"

columns are not specified in the table, they shall be as required by the referenced test method. The physical and

chemical values specified in section 3 apply to the average of the determinations made on a sample unit for test

purposes as specified in the applicable test methods. The sample size shall be in accordance with table IV. The

sample unit for testing shall be one tube or spool of twine. The lot size shall be expressed in units of one tube or

spool. All test reports shall contain the individual values utilized in expressing the final result. The lot shall be

unacceptable if one or more units fail to meet any requirement. Tests to determine compliance with specification

requirements, including quantity of delivery, may be made under prevailing atmospheric conditions. In cases of

dispute, tests shall be made upon material which has reached equilibrium under Standard Conditions as defined in

FED-STD-191.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business