MIL-DTL-713F

3.4

Finish.

Type N, waxed twine. The type N twine shall be uniformly mildew resistant and microcrystalline wax

3.4.1

treated. The mildew resistant treatment shall conform to the requirements for type I, class 2 inhibitor of MIL-T-

3530. The inhibitor may be applied with the microcrystalline wax treatment. The treatment utilized shall not contain

copper or mercury, or compounds of copper or mercury.

3.4.1.1

Type N, wax content. The treated type N twine shall contain a minimum of 10 percent and a maximum

of 25 percent wax when tested as specified in 4.2.4.

3.4.2

Type P waxed twine. Type P waxed twine shall be uniformly treated with a microcrystalline fungicidal

wax. The treatment utilized shall not contain copper or mercury, or compounds of copper or mercury.

3.4.2.1

Type P, wax content. The treated type P twine shall contain a minimum of 20 percent and a maximum

of 32 percent wax when tested as specified in 4.2.4.

3.4.2.2

Fungus resistance effectiveness. The type P waxed twine shall show no visible growth (to the naked

eye) on the surface of the test specimens when tested as specified in 4.2.4.

Color. Unless otherwise specified (see 6.2), the color of the twine shall be natural unbleached color of

3.5

the fiber and as naturally resulting from treatment.

3.6

Physical requirements. The finished twine shall conform to the requirements specified in table I (see 6.3)

for the respective types and classes when tested as specified in 4.2.4.

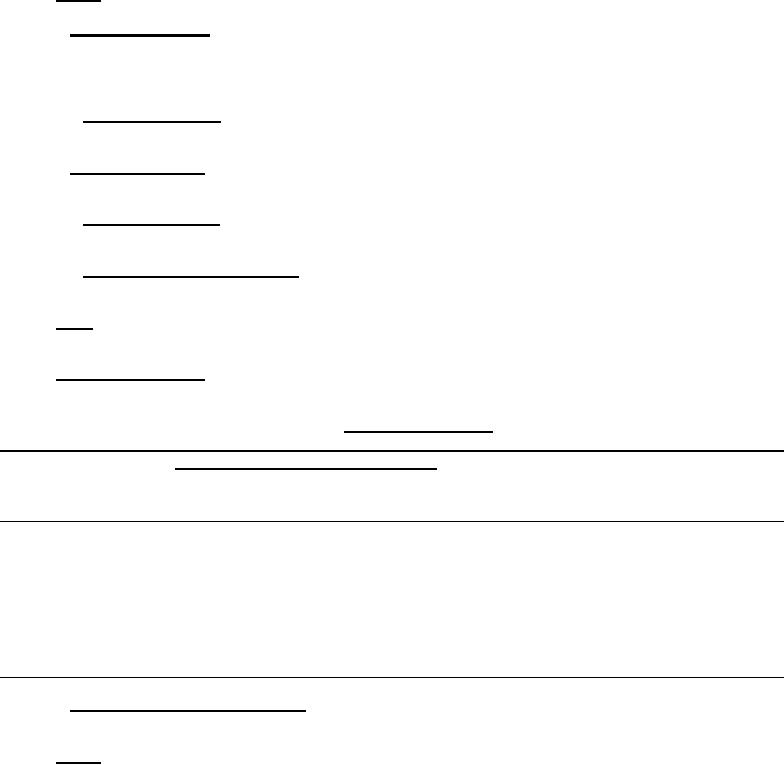

Table I. Physical requirements.

Length per pound, minimum

Elongation

waxed twine,

unwaxed twine,

Breaking strength,

maximum

Type

Class

yards

yards

minimum, pound

maximum,

percent

N

1

300

-

70.0

15.0

N

2

450

-

48.0

15.0

N

3

600

-

32.0

15.0

P

1

550

650

70.0

20.0

P

2

750

950

48.0

20.0

P

3

1100

1400

32.0

20.0

3.6.1

Stiffness (applicable only to type N). The type N twine shall not deflect more than 1/8 inch when tested

as specified in 4.2.4.

3.7

Put-up. Unless otherwise specified (see 6.2), the twine shall be furnished in 1 pound net weight tubes

or spools. A plus or minus tolerance of 10 percent shall be permitted on the weight of any one tube or spool

provided the average weight does not fall below 1 pound. The twine shall be wound in such a manner that each

turn and layer is free from entanglement. A maximum total of two knots or laid-on ends or combination thereof per

tube or spool shall be permitted. No piece of twine shall be less than 16 yards in length. The empty tube or spool

shall measure 1 ± ¼ inch inside diameter, 1-1/4 ± ¼ inches outside diameter, and 4-1/8 ± ¼ inches in length.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business