MIL-DTL-24050E

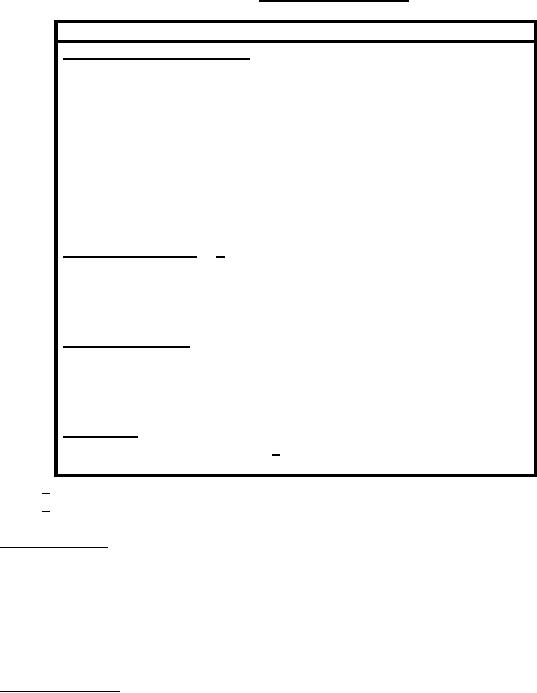

TABLE VIII.

Classification of defects.

Defects

Appearance and workmanship

Loose fit of cover on the core.

Cut, any.

Chafed or damaged.

Kinks or uneven braiding resulting in open places, breaks in

continuity of braid, or soft spots.

Broken, loose, or projecting ends in the core or cover.

Excessive loose fiber ends on surface, gaps between strands.

End not cut off squarely.

End not securely whipped, taped, or heat sealed.

Identification marker. 1/

Omitted, incorrect, illegible.

Italic or script type used, not as specified.

Not completely covered by the outer braid.

Identification ticked.

Omitted, incorrect, illegible.

Insecurely attached.

Handwritten entries.

Cleanliness.

Spot or stain clearly visible. 2/

1/ Identification marker for braids larger than 1 - 1/8 inch circumference.

2/ At normal inspection distance (approximately 3 feet).

4.4.2.1 Defects in length. Defects with regard to length shall exist if any of the following are determined

during inspection:

(a) Length of unit less than or more than length specified (including permitted tolerances).

(b) Length of unit less than marked on ticket.

(c) Reels not in continuous length.

(d) Any piece on reels less than 600 feet in length for ropes with a circumference of 3/4 inch up to

16 inches.

4.4.2.2 Defects in winding. Defects with regard to winding shall exist if the following are determined during

inspection:

(a) Improperly or not firmly wound resulting in slippage during unwinding or otherwise affecting

free unhampered unwinding of rope.

(b) Knot or splice joining ends to make a continuous length.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business