MIL-DTL-24050E

3.11 Workmanship. The ends of all rope shall be cut off squarely and be securely whipped, tape, or heat

sealed. The reels shall be wound so that each turn and layer is free from entanglement. The component braid and

the finished braided rope shall conform to quality and grade of product established by the requirements of this

specification.

4.

QUALITY ASSURANCE PROVISIONS

4.1 Classification of inspections.

The inspection requirements specified herein are as follows:

(a) First article inspection (see 4.2)

(b) Quality conformance inspection (see 4.3)

4.2 First article inspection. First article inspection shall consist of the examinations specified in 4.4.1 and

4.4.2 and tests specified in 4.5.

4.2.1

First article sample.

The first article sample for ropes shall be a continuous finished length of 70 feet.

4.3 Quality conformance inspection. Quality conformance inspection shall consist of the examinations

specified 4.4.1 and 4.4.2 and the tests specified in 4.3.1 and 4.5 (see 6.3). Unless otherwise specified herein,

sampling for inspection shall be performed in accordance with tables V an VI.

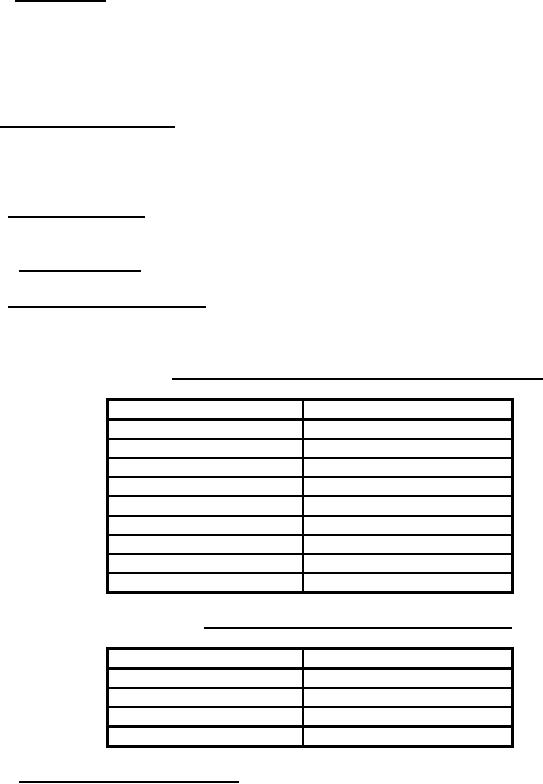

TABLE V.

Sampling for visual examination and testing of the end item.

Lot size

Sample size

2 -

15

2

16 -

25

3

26 -

90

5

91 -

150

8

151 -

280

13

281 -

500

20

501 - 1200

32

1201 - 3200

50

3201 - 10000

80

TABLE VI

Sampling for examination for length and winding.

Lot size

Sample size

1 -

10

All

11 -

500

10

501 - 3200

13

3201 - 10000

20

4.3.1 Material and component inspection. Determination shall be made for all characteristics of components

specified in table VII, except material (see 6.3) and appendix). The linear density per filament and the tenacity of

the fiber shall be determined in accordance with ASTM D885, D 1577 and D 2258. Results shall be determined as

pass or fail.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business