MIL-DTL-24050E

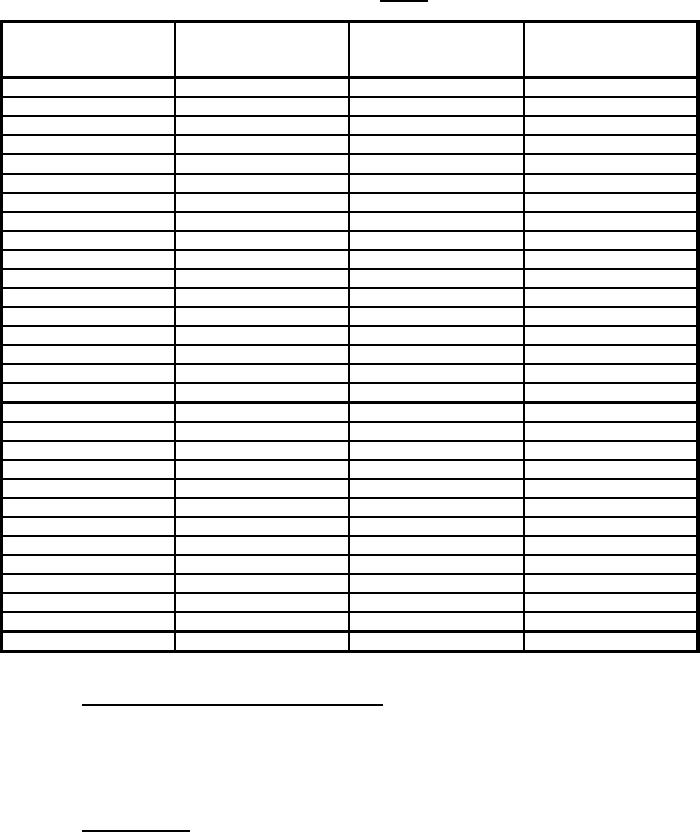

TABLE IV.

Put-Up.

Circumference

Diameter

Standard length

Net weight per

(inches)

(inches)

(feet)

standard length

(pounds)

3/4

1/4

600

9.6

1

5/16

600

15

1 - 1/8

3/8

600

21.5

1 - 5/16

7/16

600

29.3

1 - 1/2

1/2

600

38.2

1 - 3/4

9/16

600

52.1

2

5/8

600

68

2 - 1/4

3/4

600

86.3

2 - 1/2

13/16

600

106

2 - 3/4

7/8

600

128

3

1

600

153

3 - 1/2

1 - 1/8

600

209

3 - 3/4

1 - 1/4

600

239

4

1 - 5/16

600

273

4 - 1/2

1 - 1/2

600

344

5

1 - 5/8

600

426

5 - 1/2

1 - 3/4

600

517

6

2

600

612

6 - 1/2

2 - 1/8

600

718

7

2 - 1/4

600

832

7 - 1/2

2 - 1/2

600

958

8

2 - 5/8

600

1090

9

3

600

1380

10

3 - 1/4

600

1700

11

3 - 1/2

600

2060

12

4

600

2450

13

4 - 1/4

600

2840

14

4 - 1/2

600

3300

15

5

600

3780

16

5 - 1/4

600

4320

3.10.1.2 Continuous lengths greater than standard lengths. To compensate for random strand failures when

continuous lengths are greater than standard lengths and up to 1200 feet maximum, an additional braider splice

shall be permitted in the core and in the cover. In producing the splices the distance of the overlapping shall be

equivalent to 8 times the circumference in inches but not less than 24 inches for ropes whose sizes are 3 inches in

circumference and less. If more than one of these splices are in the same strand they shall be at least 20 feet apart

measured from splice center to splice center.

3.10.1.3 Splice acceptance. Because splices within the core are difficult to detect after application of the

cover, a record of verifiable information attesting to the number of braider splices shall be available to the

inspector.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business