MIL-DTL-24050E

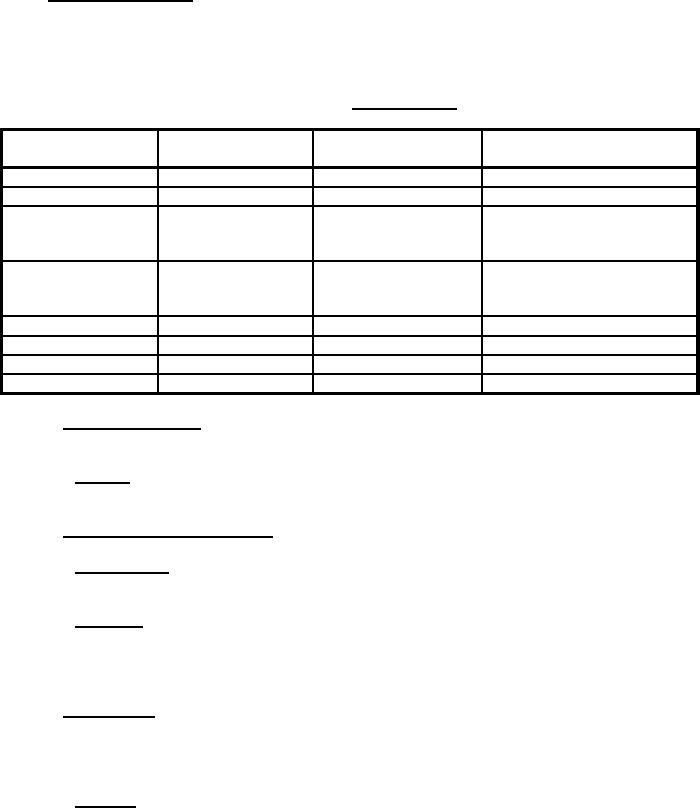

4.5 Testing of the end item. Testing of the end item shall be as specified in table IX and 4.5.2 through 4.5.9.

The physical and chemical values specified in section 3 apply to the average of the determination made on a

sample unit for test purposes as specified in the applicable test methods. The sample size shall be as specified in

table V and the presence of any defect shall be cause for rejection of the entire lot. The lot size shall be expressed

in units of reels. The sample unit for test purposes shall be 70 feet.

TABLE IX.

End item testing.

Number of determinations per

Characteristics

Requirement

Test method

individual sample unit

Circumference

3.5

4.5.2.1

3

Linear density

3.5

4.5.3

1

Breaking strength

3.5

4.5.4

2 (up to 9 - inch circumference)

1 (10 - inch circumference and

above)

Elongation

3.5.1

4.5.5

2 (up to 9 - inch circumference)

1 (10 - inch circumference and

above)

Extractable matter

3.6

4.5.6

2

Identification marker

3.8

4.5.7

1

Moisture content

3.7

4.5.8

2

Cover to core ratio

3.4

4.5.9

2

4.5.1 Specimen preparation. The designated length and number of test specimens shall be removed from the

selected test reels in accordance with the specified test method.

4.5.1.1 Splicing.

For each specimen; each end shall have a buried eye splice as recommended by the

manufacturer.

4.5.2

Circumference and picks per inch.

4.5.2.1 Circumference. The circumference shall be measured in accordance with method 6003 of FED-STD-

191. Results to be reported shall be the average of 3 determinations to the nearest 1/16 inch.

4.5.2.2 Pick count. While under load P, 10 complete picks shall be counted and marked off. The distance

between marks shall be measured to the nearest 1/16 inch. This procedure shall be repeated at least 3 times in

different positions (not less than 1 foot of rope apart). The multiplier value specified in table II shall be calculated

for the respective sizes by dividing 10 by the observed dimension and multiplying the result by the circumference.

4.5.3 Linear density. The liner density shall be determined in accordance with method 6004 of FED-STD-

191. Tests to determine compliance with the requirements (including quantity of delivery) specified herein may

be conducted under prevailing atmospheric conditions. In case of dispute, the tests shall be conducted on material

which has reached equilibrium under standard conditions specified in method 6015 of FED-STD-191.

4.5.3.1

Accuracy.

Linear density results determined shall be as specified in Table X.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business