MIL-DTL-24050E

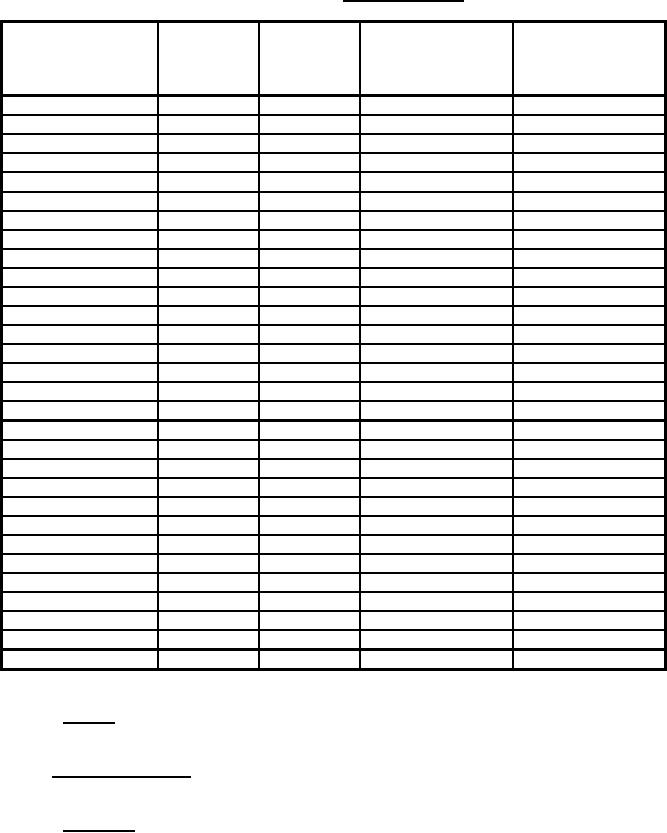

TABLE III.

Physical Properties.

Circumference

Diameter

Linear density

at load P

(nominal

Load P

plus or minus

Breaking strength

(nominal inches)

inches)

(pounds)

5 percent

(minimum pounds)

(pounds/100 feet)

3/4

1/4

13

1.52

1785

1

5/16

20

2.38

2835

1 - 1/8

3/8

28

3.42

4095

1 - 5/16

7/16

38

4.65

5355

1 - 1/2

1/2

50

6.06

7245

1 - 3/4

9/16

63

8.26

9450

2

5/8

78

10.8

12600

2 - 1/4

3/4

113

13.9

15750

2 - 1/2

13/16

132

16.7

19320

2 - 3/4

7/8

153

20.4

23625

3

1

200

24.3

27825

3 - 1/2

1 - 1/8

253

33.1

37800

3 - 3/4

1 - 1/4

313

38.0

44100

4

1 - 5/16

345

43.3

50400

4 - 1/2

1 - 1/2

450

54.6

64200

5

1 - 5/8

528

67.6

78110

5 - 1/2

1 - 3/4

613

82.0

96300

6

2

800

97.1

109675

6 - 1/2

2 - 1/8

903

114.0

131610

7

2 - 1/4

1013

132.0

149800

7 - 1/2

2 - 1/2

1250

152.0

171200

8

2 - 5/8

1378

173.0

192600

9

3

1800

219.0

243000

10

3 - 1/4

2113

270.0

284840

11

3 - 1/2

2450

327.0

351000

12

4

3200

389.0

415800

13

4 - 1/4

3613

450.0

475200

14

4 - 1/2

4050

524.0

548640

15

5

5000

600.0

622080

16

5 - 1/4

5513

685.0

702000

3.4.3 Texture. The texture of the finished rope shall be firm without sleaziness, and the cover (outer braid)

shall fit closely around the core (inner braid) when inspected with the rope in a relaxed state.

3.5 Physical requirements. The finished rope shall conform to the physical properties specified in table III

when tested as specified in 4.5. The circumference in accordance with table III shall be as specified (see 6.2).

3.5.1 Elongation. The elongation of the ropes shall not exceed 40 percent at the minimum breaking strength

when determined as specified in 4.5.5. The load elongation curve, drawn autographically, shall not exhibit

evidence of sudden changes in load applications greater than 5 percent of the load weighted at the instant of

change. Changes due to splice slippage shall not be considered in this determination.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business