MIL-DTL-1688G

4.4.3 End item length and winding examination. The rope shall be examined for the defects listed below. The lot size

shall be expressed in units of coils of rope. The sample unit shall be one coil of rope. Defects shall be as listed below.

The inspection level shall be S-3, and the AQL, expressed in terms of defects per hundred units, shall be 4.0. the

required length of the coil (see table II) shall be determined using the following formula:

W x L = Length per coil in feet.

When W = the net weight of the coil in 0.1 pound.

L = the lot average of the weight-length relationship (length/pound) as specified in

table I.

Defects

Length of rope is less than specified or more than length specified (see table II).

Length of rope on coil is more than 6 feet less than the length indicated on the ticket.

Improperly or not firmly wound resulting in kinking, knotting, entangling, or slippage during

unwinding, or otherwise affecting free unhampered unwinding of rope.

Any end frayed or not cut off squarely or neatly.

Any end not securely whipped or heat sealed.

4.4.4 End item testing. The end items shall be tested for the characteristics listed in table V. The methods of testing

specified in FED-STD-191, wherever applicable, and as listed in table V shall be followed. When the data in the

"Number of determinations" and "Results reported as" columns are not specified in table V, they shall be as required by

the referenced test method. The physical and chemical values specified in section 3 apply to the average of the

determinations made on a sample unit for test purposes as specified in the applicable test methods. The lot size shall

be expressed in units of coils of rope. The sample unit shall be one coil of rope. The sample size shall be in

accordance with table VI. The lot shall be unacceptable if one or more sample units fail to meet any requirement. All

test reports shall contain the individual values utilized in expressing the final results. Tests to determine compliance

with document requirements may be made under prevailing atmospheric conditions. In case of dispute, tests shall be

made upon material that has reached equilibrium under standard conditions as defined in FED-STD-191.

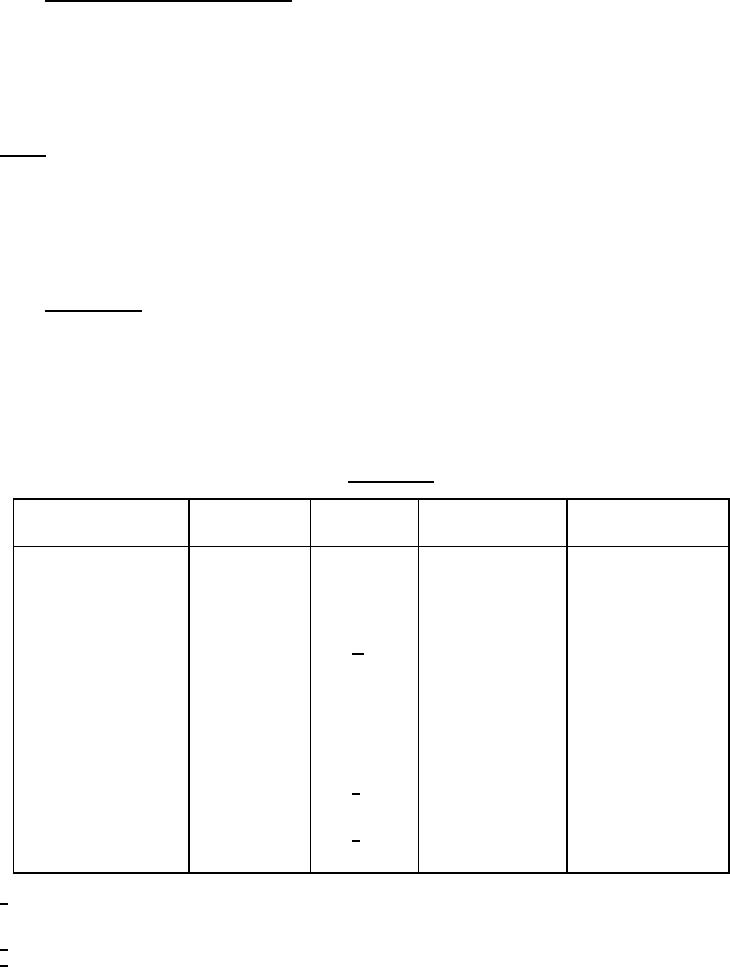

TABLE V. End item tests

Number of

Requirement

determinations

Results

Characteristic

reference

Test method

per sample unit

reported as

Number of strands

3.5

Visual

1

Pass or fail

Lay of rope

3.5

Visual

1

Pass or fail

Shrinkage

3.5

6010

-

-

Circumference

Table I

6003

-

-

Length per pound

Table I

6004

-

-

Breaking strength:

Initial

Table I

6015 1/

-

-

After heat aging

3.5.1

6015 and

2

Average of 2

(percent strength)

4.5.1

determinations to

nearest 10 lb.

calculated to nearest

0.1 percent

Elongation

Table I

6015

-

-

Length per 10 turns

Table I

6000

-

-

Hardness

3.5.2

6020

-

-

Extractable matter

2.6

2611 2/

2

Average of 2

determinations to

nearest 0.1 percent

Colorfastness to

3.7.1

5671 3/

1

Pass or fail

weathering

pH

3.8

2811

-

-

1/ Failures in tests tend to occur at or near the end of the free length, but may occur in the mid-span between the

splices. Failures occurring within the eye splice shall be disregarded and another specimen shall be tested from the

same sample unit (see figure 1).

2/ Except that a 5-gram specimen shall be used and the extract solvent shall be petroleum ether.

3/ The specimens shall be exposed for 40 standard fading hours.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business