MIL-DTL-1688G

4.3 First article inspection. when a first article is required (see 3.1 and 6.2), it shall be examined for the

defects specified in 4.4.2 and 4.4.3 and tested for the characteristics specified in 4.4.4.

4.4 Conformance inspection. Unless otherwise specified, sampling for inspection shall be performed in

accordance with ASQ Z1.4. Unless otherwise specified, the Acceptable Quality Limits (AQLs) listed in this

section shall be used to establish the sample sizes, however, the acceptance number shall be zero.

4.4.1 Component and material inspection. Components and materials shall be inspected in accordance

with all the requirements of referenced documents unless otherwise excluded, amended, modified, or

qualified in this specification or applicable purchase document.

4.4.1.1 Component and material certification. A certificate of compliance may be acceptable as evidence

that the characteristics listed in table III conform to the specified requirements.

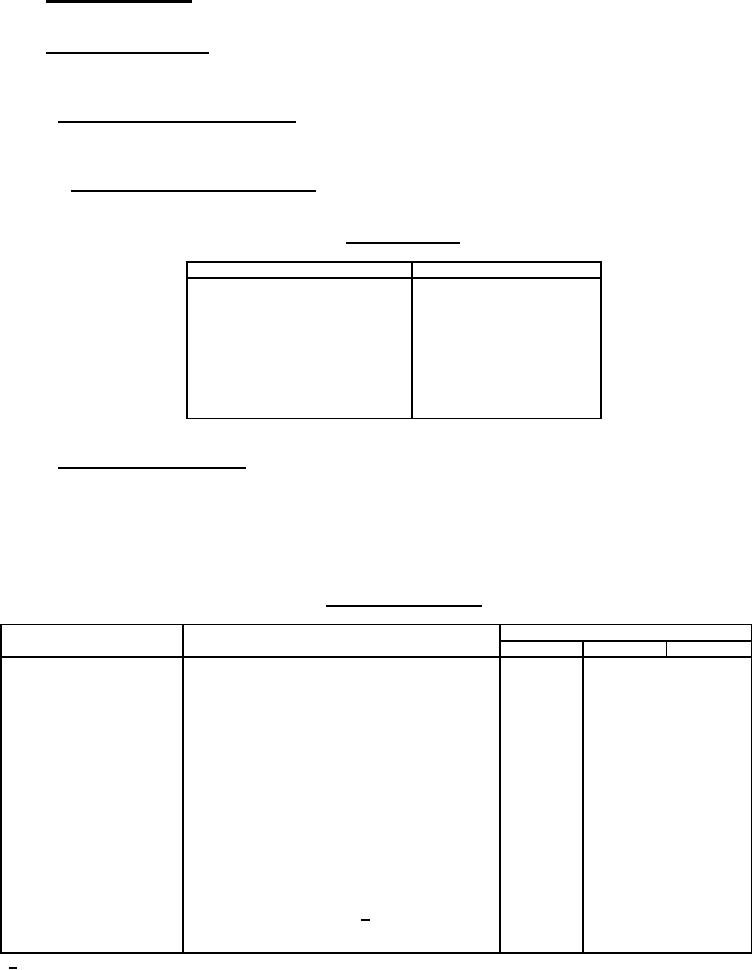

TABLE III. Component tests.

Characteristic

Requirement paragraph

Material

3.4

Denier per filament

3.4

Grams per denier strength

3.4

Light and heat resistant yarn

3.4

Fiber types mixtures

3.4

Strand construction

3.5

Denier of singles

3.5

Lay of singles

3.5

Turns per foot (singles)

3.5

4.4.2 End item visual examination. The rope shall be examined for the defects listed in table IV. All

defects shall be counted regardless of their proximity to each other. The lot size shall be expressed in units

of coils of rope. The sample unit shall be one coil of rope. One hundred feet shall be examined on each

coil of rope. The inspection level shall be II (see 6.5), and the acceptable quality limits (AQLs), expressed

in terms of defects per hundred units, shall be 1.5 for major defects and 4.0 for total (major and minor

combined) defects. Any critical defect found during sampling shall be cause for rejection of the lot

represented by the sample.

TABLE IV. End item visual defects.

Classification

Examine

Defect

Critical

Major

Minor

Appearance and

Any cut

1

workmanship

Chafed or damaged

2

Kink

3

Knot (singles, ply, strand, or rope)

5

Broken or loose end (singles, ply, strand,

or rope)

6

Bulged strand

7

Spliced or otherwise secured to make a

continuous length

8

Color

Other than specified

101

Resists and/or spotty dyeing

201

Specific shade not within established

tolerances

202

Uneven

203

Cleanness

Spot or stain, clearly visible 1/

204

Identification

Omitted, incorrect, illegible, or not as

205

1/ At normal inspection distance (approximately 3 feet).

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business