MIL-DTL-1688G

2.3 Non-Government publications. The following documents form a part of this specification to the extent

specified herein. Unless otherwise specified, the issues of these documents are those cited in the

solicitation or contract.

AMERICAN SOCIETY FOR QUALITY (ASQ)

ASQ Z1.4

- Sampling Procedures and Tables for Inspection by Attributes

(Copies of this document are available from www.asq.org or the American Society for Quality, 611 East

Wisconsin Avenue, Milwaukee, WI 53202.)

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of a conflict

between the text of this document and the references cited herein, the text of this document takes

precedence. Nothing in this document, however, supersedes applicable laws and regulations unless a

specific exemption has been obtained.

3. REQUIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first article inspection (see 6.3)

in accordance with 4.3.

3.2 Government and contractor purchase. The requirements specified in 3.9 and 3.10 apply only to rope

purchased directly by the Government. All other requirements apply both to rope purchased by a contractor

as a component for an end item and to rope purchased directly by the Government.

3.3 Materials. The rope shall be fabricated from a minimum of 6 denier per filament, bright, virgin,

continuous filament, light and heat-resistant polyamide (nylon) having a minimum 6.5 grams per denier

strength. The nylon shall be a long chain polymer made of hexamethylene diamine and adipic acid or its

derivatives, or a long chain polymer of epsilon amino caprioic acid. Mixtures of nylon fiber types (6 or 66) in

any one rope shall be prohibited. It is encouraged that recycled material be used when practical as long as

it meets the requirements of this specification.

3.4 Construction and physical requirements. The rope shall be of three strand construction and conform

to the requirements specified herein and in table I. each strand shall be made of the same size of three ply

yarns. All strands shall have an equal numbers of yarns. The singles yarn shall be between 2500 and

8000 denier. The single yarn, when measured in the three ply, shall be left-hand or "S" lay and shall have a

minimum of 22 turns per foot. The lay of the rope shall be right-hand or "Z" lay. The rope shall be heat set

and shall not show more than a 5 percent residual shrinkage when tested as specified in 4.4.4. The rope

shall be fabricated without knots or splices in the singles yarns, ply yarns, strands, or rope.

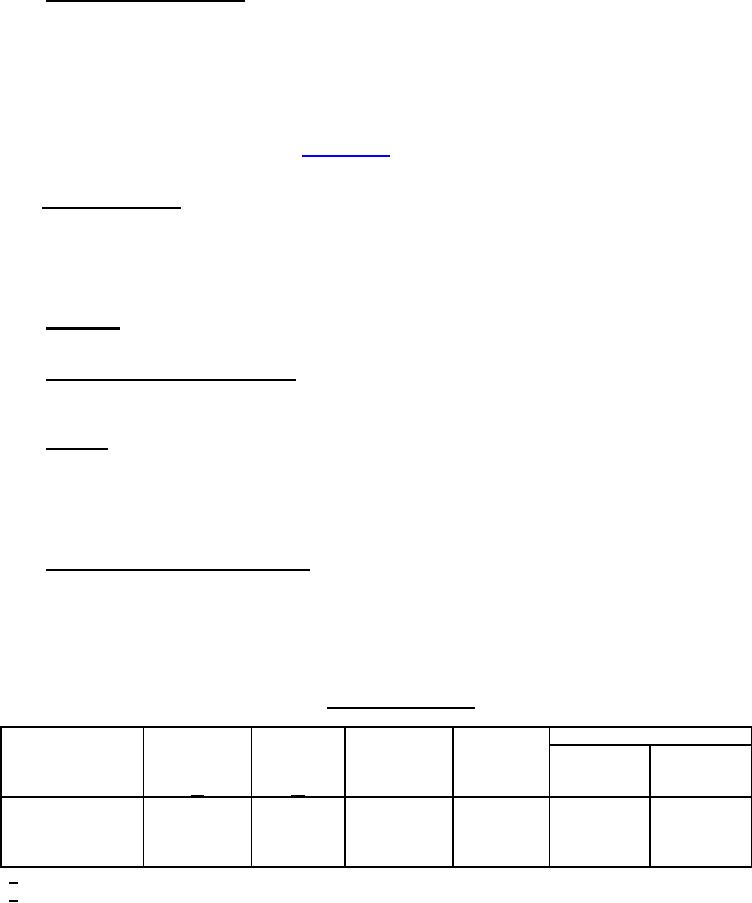

TABLE I. Physical requirements

Sizes

Diameter

Length

Breaking

Elongation

Length per 10 turns

(circumference)

approximate

feet per lb

strength

minimum

maximum

Minimum

(inches)

(inches)

minimum

minimum

(percent)

(inches)

(inches)

+1/8 , -1/16

1/

2/

(pound)

¾

¼

47.0

1300

35.0

7.8

7.0

1-1/8

3/8

23.0

3150

35.0

12.4

11.1

1-1/4

7/16

17.0

4500

35.0

14.3

12.9

1-1/2

½

8.5

6500

35.0

17.2

15.1

1/ Not a specification requirement, included for information only.

2/ A minus tolerance of 10 percent is allowed for dyed rope.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business