MIL-DTL-1688G

3.4.1 Breaking strength after heat aging. The loss in breaking strength after heat aging of the rope shall

not exceed 10.0 percent of the initial breaking strength when tested as specified in 4.4.4.

3.4.2 Hardness. The finished rope shall have a hardness of 20 ± 5 pounds when tested as specified in

4.4.4.

3.5 Extraneous material. No extraneous material shall be added for the purpose of weighting the rope.

The extractable matter of the finished rope shall not exceed 4.0 percent when tested as specified in 4.4.4.

3.6 Color. Unless otherwise specified (see 6.2), the rope shall be dyed with color chip number 34094 per

FED-STD-595.

3.6.1 Colorfastness. The dyed and finished rope shall show fastness to weathering equal to or better than

a rating of "fair" when tested as specified in 4.4.4.

3.7 pH. The pH value of the rope shall be within the range of 5.0 to 9.0 when tested as specified In 4.4.4.

3.8 Identification. Each coil of rope shall have a ticket (identification tag) attached for identification

purposes. The ticket shall conform to the requirements of A-A-59622 and shall contain the following

information:

National stock number

Nomenclature

Specification number

Length

Size (circumference)

Contract number and date

Contractor's name

Date of manufacture (month and year)

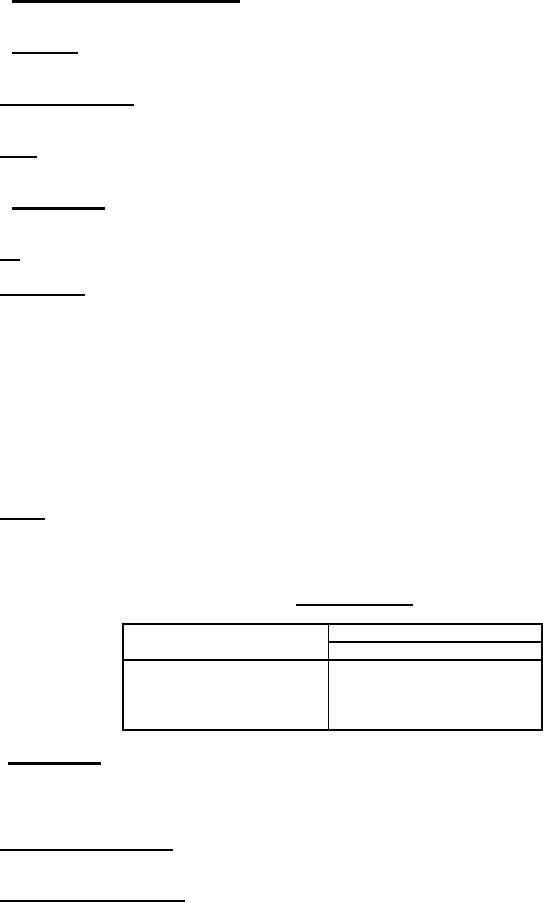

3.9 Put-up. Unless otherwise specified (see 6.2), the rope shall be put-up in coils in lengths specified in

table II for the respective sizes (circumference). The rope, when put-up in coils as specified in table II, shall

be in one continuous piece and so wound that each turn and layer is free from entanglement. The ends of

all rope shall be cut off squarely and securely whipped or heat sealed to prevent fraying or untwisting.

TABLE II. Put-up coil length.

Rope size

Coil length (feet)

(circumference in inches)

minimum

maximum

¾

196

204

1-1/8

196

204

1-1/4

117

123

1-1/2

117

123

3.10 Workmanship. The material shall be manufactured and processed in a manner that will insure its

meeting all the requirements of this specification..

4. VERIFICATION

4.1 Certificates of compliance. When certificates of compliance are submitted, the Government reserves

the right to inspect such items to determine the validity of the certification.

4.2 Classification of inspections. The inspection requirements specified herein are classified as follows:

a. First article inspection (see 4.3).

b. Conformance inspection (see 4.4).

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business