MIL-DTL-24677B

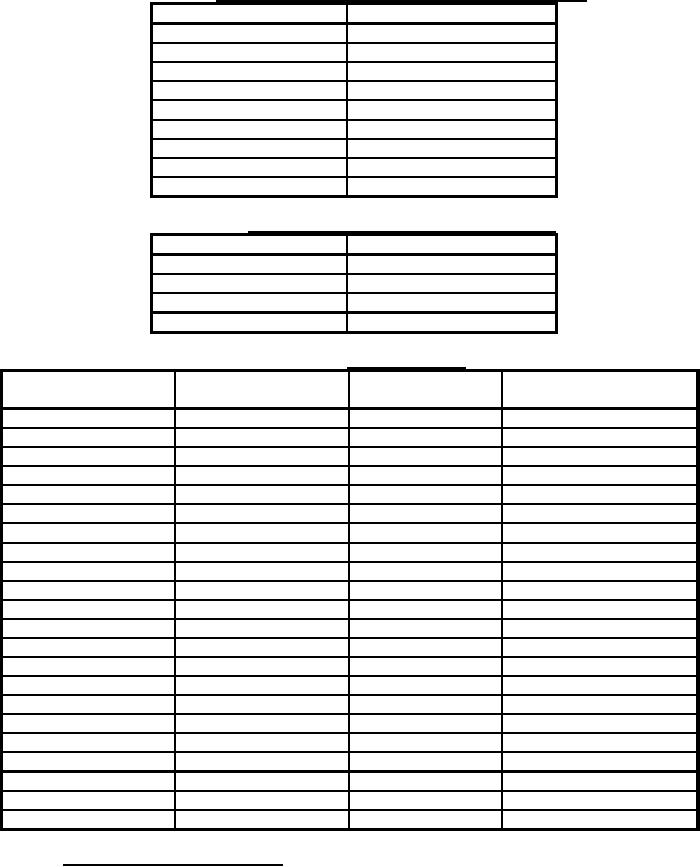

TABLE V.

Sampling for visual examination and testing of the end item.

Lot size

Sample size

2 -

15

2

16 -

25

3

26 -

90

5

91 -

150

8

151 -

280

13

281 -

500

20

501 - 1200

32

1201 - 3200

50

3201 - 10000

80

TABLE VI Sampling for examination for length and winding.

Lot size

Sample size

1 -

10

All

11 -

500

10

501 - 3200

13

3201 - 10000

20

TABLE VII.

Component testing.

Number of determinations

Characteristics

Requirement

Test method

per individual sample unit

Fiber:

Type

3.3

4.3.1

1

Linear density

3.3

4.3.1

1

Tenacity

3.3

4.3.1

1

Outer braid:

Yarn size

3.4.1

Visual

1

Yarns per strand

Table II

Visual

1

Number of strands

Table II

Visual

1

Braid type

Table II

Visual

1

Multiplier

Table II

4.5.2.2

3

Heat setting

3.4

4.3.1

1

Braider splices

3.10.1

4.3.1

Marine finish

3.3.1

4.3.1

Inner braid:

Yarn size

3.4.1

Visual

1

Yarns per strand

Table I

Visual

1

Number of strands

Table I

Visual

1

Braid type

Table I

Visual

1

Multiplier

Table I

4.5.2.1

3

Heat setting

3.4

4.3.1

1

Braider splices

3.10.1

4.3.1

1

Marine finish

3.3.1

4.3.1

4.3.1 Material and component inspection. Determination shall be made for all characteristics specified in

table VII, except material (see 6.3 and appendix). The linear density per filament and tenacity of the fiber shall be

determined in accordance with ASTM D885, D1577 and D2258. Results shall be as pass or fail.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business