MIL-DTL-24677B

4.5.2.2 Pick count. While under load P, ten complete picks shall be counted and marked off. The distance

between the marks shall be measured to the nearest 1/16 inch. This procedure shall be repeated at least three times

in different positions (not less than 1 foot of rope apart). The multiplier value specified in table II shall be

calculated for the respective sizes by dividing 10 by the observed dimension and multiplying the result by the

circumference.

4.5.3 Linear density. The linear density shall be determined in accordance with method 6004 of FED-STD-

191. Tests to determine compliance with the requirements (including quantity of delivery) specified herein, may

be conducted under prevailing atmospheric conditions. In case of dispute, the tests shall be conducted on material

which has reached equilibrium under standard conditions specified in method 6015 of FED-STD-191.

4.5.3.1

Accuracy.

Linear density results determined shall be in accordance with Table X:

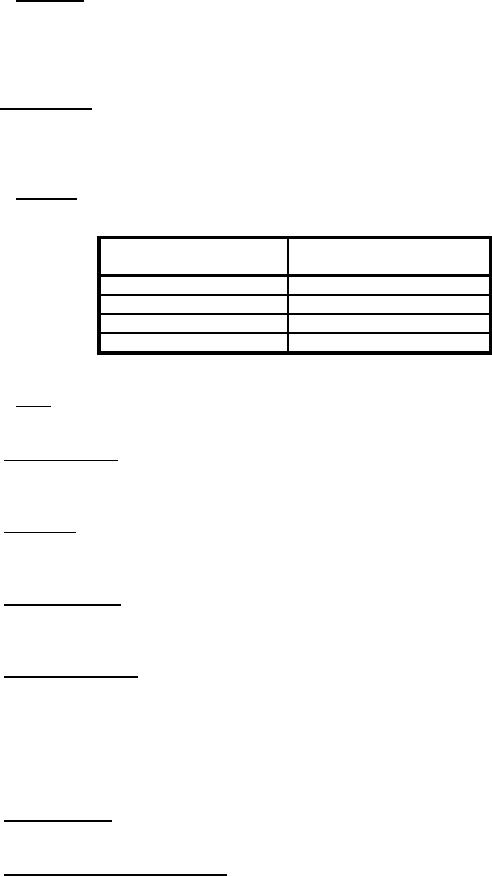

TABLE X

Circumference

Degree of accuracy

(inches)

(pounds per 100 feet)

Less than 1 - 3/4

Nearest 0.01

2 to 6

Nearest 0.1

6 - 1/2 to 12

Nearest 1.0

More than 12

Nearest 10.0

4.5.3.2 Load. The load applied need not cause a rope failure provided all individual test values exceed the

specified minimum breaking strength.

4.5.4 Breaking strength. Breaking strength determinations shall be conducted in accordance with method

6015 of FED-STD-191. Results shall be the average determination to an accuracy of 1 percent, but no single

breaking strength test below the minimum values listed in table III shall be considered acceptable.

4.5.5 Elongation. The elongation at a minimum breaking strength shall be determined in accordance with the

initial single loading procedure of method 6015 of FED-STD-191. The results shall be the average of

determination to the nearest 0.1 percent.

4.5.6 Extractable matter. The extractable content shall be determined in accordance with ASTM D 2257,

using a Soxhlet apparatus in the procedure. Results shall be the average of two determinations to the nearest 0.1

percent.

4.5.7 Identification marker. Three lengths of the identification marker shall be used to determine the fastness

of printed matter of the identification marker to saltwater and mineral oil. Each length shall be approximately 1-

1/2 feet. One length shall be retained as a control, one length shall be immersed for 2 hours in synthetic seawater

conforming to ASTM D 1141, stock solution number 1, 2, or 3, and one length shall be soaked for 2 hours in

mineral oil conforming to symbol 2190-TEP of MIL-L-17331. Following removal from the respective

environments, the two exposed specimens shall be visually compared with the control specimen. The fastness of

the printed matter shall be considered satisfactory when no perceptible change in color of legibility is observed.

4.5.8 Moisture content. The moisture content shall be determined in accordance with method 2600 of FED-

STD-191. Results shall be the average of two determinations to the nearest 0.1 percent.

4.5.9 Determination of cover to core ratio. A two foot specimen shall be cut off, after which the cover shall be

separated from the core. The cover and core shall be weighed separately and the percentage of each by weights

shall be determined for compliance with 3.4. Results shall be the average of the two determinations to the nearest

0.1 percent.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business